Geophones are complex mechanical devices manufactured using a range of materials; metal alloys (spring, coil, housing), plastics (outer case), rare earth material (magnet). The properties of these materials are subject to ageing during their lifetimes (spring creeping/hardening, demagnetization) and drift due to thermal changes (coil resistance, spring stiffness, etc).

Geophone sensitivity is mainly determined by the spring stiffness, electromagnetic field induced by the permanent magnet, and the coil mass. All of these parameters are subject to ageing, drift and manufacturing tolerance.

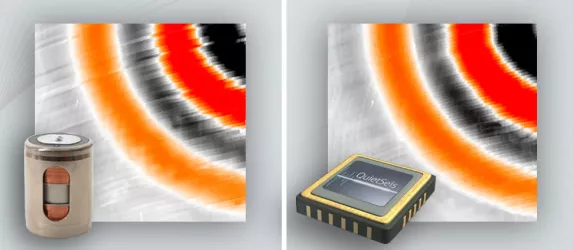

Sercel MEMS accelerometers are fabricated using a 100% silicon substrate, a material known for its stability, immunity to ageing and minimal thermally induced drift of its mechanical or electrical properties. The sensitivity of Sercel’s QuietSeis® sensors (closed loop MEMS accelerometer) is in fact only determined by the silicon electrode size (manufactured using techniques similar to those used in microelectronics with submicron tolerances) and by the applied voltage that can be set with extremely high degrees of accuracy.

Sensor related data jitter is therefore a phenomenon observed only in geophones being especially evident in high sensitivity geophones. While amplitude data jitter will affect the full seismic frequency band, phase data jitter will also have a significant impact at lower frequencies.

Learn more about the major benefits of using the latest generation of MEMS sensors over geophones in our abstract.