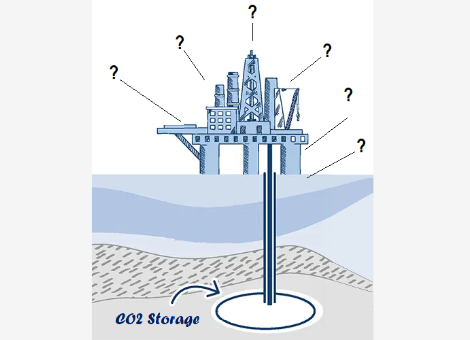

Challenges in repurposing offshore platforms for CO2 injection

Offshore platforms were originally designed for oil and gas production and extraction, not for CO2 transport and injection. Materials must be adapted to this new CO2 injection activity.

- Adaptation of materials to CO2 properties

- Foundation integrity

- Management of old wells

- Pipeline design constraints

- Interactions with marine environment

The major challenges listed are related to the structural capabilities of the platform for CO2 injection.

What are the structural challenges?

Here are some of the key structural challenges that companies must address to extend platform life for CO2 injection.

Adaptation of materials to CO2 properties

- Corrosion and embrittlement:

Injected CO2 is often in a supercritical phase, which increases its density and its interactions with materials. In the presence of water, it forms carbonic acid, which is highly corrosive. Pipelines, valves, and other metal components must therefore be reinforced or replaced with corrosion-resistant materials. Existing welds and seals must be evaluated to withstand these new stresses. - Temperature and pressure:

Structures must be adapted to the pressure and temperature variations associated with CO2 injection, which are different from those encountered during hydrocarbon extraction.

Foundation integrity

- Aging structures:

Many offshore platforms reach the end of their life after decades of oil or gas exploitation. Material fatigue and degradation of subsea foundations can limit their ability to be converted. Conversion of platforms for CO2 injection involves extending their lifespan well beyond the original design life. Aging structures must be evaluated and monitored to ensure reliability over several decades. - Loads and vibrations:

New dynamic loads generated by injection equipment (compressors, pumps, etc.) require a thorough structural assessment to ensure the stability of foundations and superstructures.

Reinforcement of lifting and handling systems: CO2-related operations require appropriate lifting infrastructure to handle heavy equipment and ensure offshore maintenance.

Management of old wells

- Risk of leakage from old wells:

Wells drilled for hydrocarbon production must be properly sealed to prevent them from becoming leak paths for injected CO2. These often old wells may have structural failures that require costly cementing or renovation operations. - Leak detection and prevention:

Platforms must be equipped with sensors and monitoring systems to detect any CO2 leakage through the structures or the injection well.

Pipeline design constraints

- Offshore pipelines adaptation:

Existing hydrocarbon transport pipelines must be inspected or replaced to carry supercritical CO2 with increased pressure and corrosion resistance requirements. The curvature of the pipelines and their connections to the platform must be reassessed to avoid weak points.

Interactions with the marine environment

- Protection from environmental stresses:

Platforms must continue to withstand wave, current, and wind forces while supporting additional equipment. Any vibration from new systems can interact with these forces and affect overall integrity. - Erosion and biofouling:

Prolonged exposure to the marine environment accelerates erosion and biofouling (biological colonization), which can weaken structures over time.

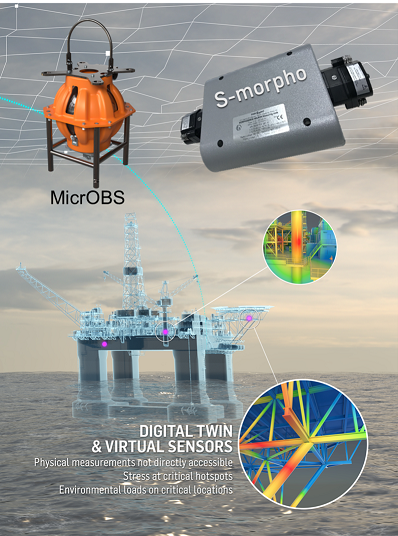

THE VALUE PROPOSITION OFFERED BY SERCEL:

- Rapid deployment capability in an ATEX (explosive atmosphere) environments

- Quasi real-time data processing

- Correlation of structural behavior with O&G platform environment and activities

- True digital twin

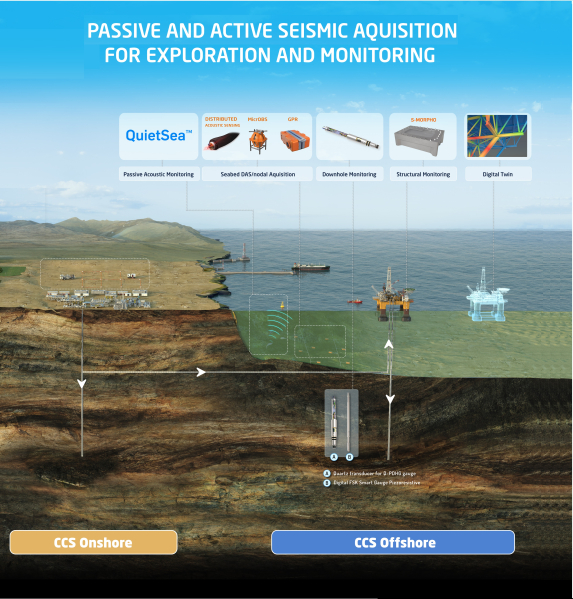

- Seabed monitoring by seismic or micro-seismic acquisition to monitor the effect of the injected CO2

CONCLUSION

The structural challenges of reusing offshore platforms for CO2 injection require a thorough assessment of existing infrastructure and substantial investment in adaptation. Success will depend on the ability to develop robust technologies, evaluate and extend the life of structures while ensuring their integrity, and minimize the environmental impact on the marine ecosystem.

With multiple offerings such as MicrOBS, a powerful ocean bottom seismometer for monitoring during injection, and the S-morpho real-time Digital Twin solution, Sercel can provide customers with monitoring during injection, life extension and platform fatigue estimation.

Learn how Perenco uses MicrOBS for seismic monitoring during a CO2 injection test in a depleted gas reservoir.