Overview

Highlights

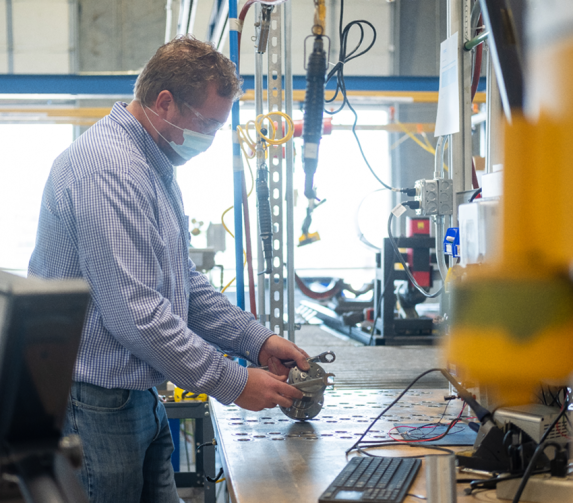

Spy Pro brings many financial benefits to the customer, including the reduction of well intervention, risk, liability and costs for all parties involved. It also optimizes pump performance, run life and oil production, while protecting your people, the pump and reservoir. Eliminating pump shutdown with sensor troubleshooting, the Spy Pro ESP monitors and protects your well.

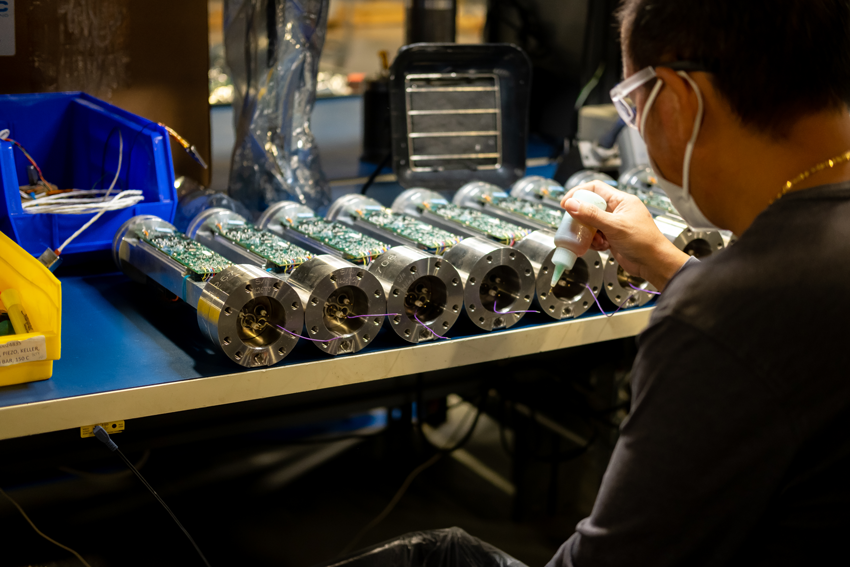

• Unique Mechanical Concept: Precision Welded (Sealed) design eliminates the need of re-dressing and contamination.

• Intake Pressure being read internally from the motor oil, enables auditing the integrity of the seals and not being in contact with any harsh well fluids.

Key Benefits

ESP MOTOR WYE

- Point imbalance true downhole measurement allows understanding the trend of the electrical health of your ESP and easily determining if the gauge has: failed; can’t communicate to surface due to high imbalance; or it’s grounded.

- Gauge wiring to motor is fuse protected to avoid affecting the motor performance. Motor winding temperature can be read with RTD and Thermocouple options.

uCOMMAND

- Enables, under VSD energized conditions or RiH, to tailor the channels of data to be collected, transmitted, and stored at surface.

HIGH SPEED DATA

- High speed data extends use of gauge in reservoir and well testing applications; and improves root cause analysis while still in the hole!